On the PROTIQ Marketplace, customers can find configurable gears to meet any geometric requirement and go far beyond the standard catalogue - enabled by additive manufacturing and our paramate software.

Mass Customization - Highly relevant, especially in industrial markets

In industrial environments, there are numerous situations in which components such as gears, for instance, are required in specific geometries and small quantities at the same time.

- In the prototyping sector, for example, custom geometries are frequently common. For these, it would be inefficient in the first step to manufacture the respective tools for the production of larger quantities (e.g. by injection moulding). On the contrary, this expensive and time-consuming step would only be taken once the final design of the gears has been confirmed.

- Quite often, larger quantities are not even planned from the beginning in industrial contexts. In small series production, tool making can still be unprofitable even after the initial prototyping phase. At the same time, the range of standard geometries does not necessarily cover the required parts.

- In the spare parts sector, geometries are frequently required that are no longer in stock and perhaps not even produced anymore. By the way, this is not only true in industrial environments, but also for private DIY enthusiasts, e.g. in the old-timer sector. In this scenario, it has to be added that the corresponding CAD data may not be available for all gears - especially for older products. However, since the gears are no longer damage-free, a scan and re-engineering based on the part itself is not an option to get the needed CAD data.

Additive manufacturing - cost-efficient particularly for small quantities

For all of these scenarios, additive manufacturing offers a cost-efficient production alternative to conventional manufacturing, since only small production quantities of a specific gear version are desired. The PROTIQ GmbH, a subsidiary of the Phoenix Contact Group and specialist for additive manufacturing in industrial quality, provides the appropriate production capacities to meet exactly this demand. This equally applies to plastic and metal printing processes.

No mass customization without an automated design process

While the manufacturing costs for the special geometries remain within reasonable ranges thanks to additive technology, another cost aspect gets more crucial for the companies and persons involved: the creation of 3D design data for the corresponding gear geometries. Usually these have to be designed manually in conventional CAD programs, since standard geometries are not at hand. This is a quite complex task that can take several hours even for experienced industrial designers.

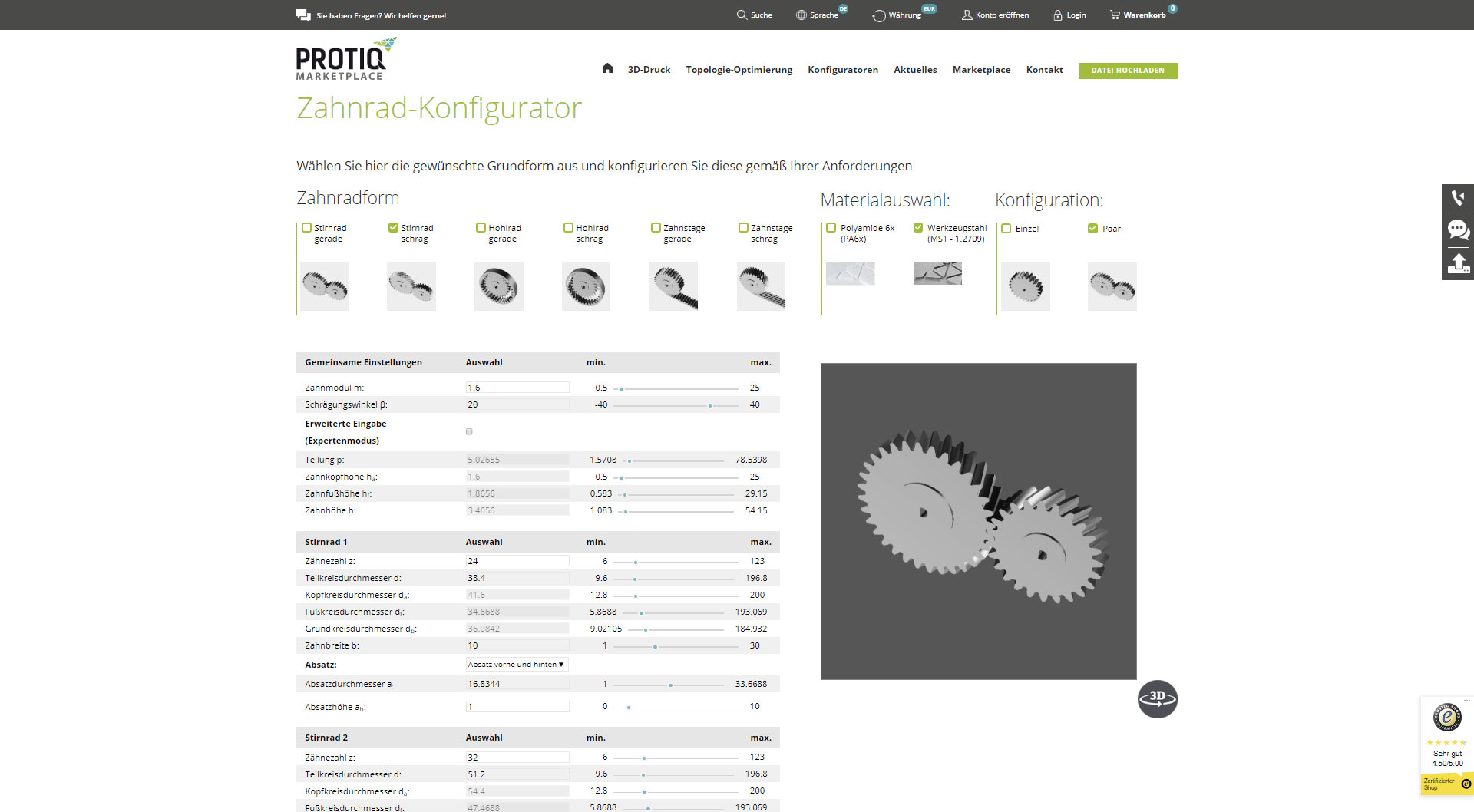

Here, the online configurator for gear systems on the PROTIQ Marketplace offers a relevant advantage for the customer. In just a few minutes, the customer can design a custom gear and order the required quantity immediately. Behind the online configurator you will find the proven paramate cloud technology.

Full flexibility for technical users - without unnecessary complexity

Similar to the inductor configurator, the user can choose from three basic variants: spur gear, ring gear and rack. These can be straight or slanted. The user is also free to decide whether he would like to configure a single gear or a pair of gears simultaneously.

The selected base type can be specified by the user via more than 20 parameters, such as number of teeth, face width, helix angle, pitch diameter or type of axle hole. This way the user, in this case a technically experienced person, has the full range of configurability at his hands, but still reaches the required result intuitively and in a few minutes.

“With the gear configurator, we offer our customers the opportunity to create their individual gear model with just a few clicks, no matter how unusual the specific geometry might be. Customers should no longer have to choose between several hours of CAD work and second-best standard shapes if they have specific requirements. With trinckle paramate we can provide our customers this additional service”

DR. RALF GÄRTNER, MANAGING DIRECTOR OF PROTIQ GMBH.

Immediate potential for savings

For the customer this service has an immediate savings potential. While a pair of gears usually requires about two hours of manual design time, the online configuration takes just 5 minutes. Assuming an estimated €100 rate per hour, the savings are almost €200 per configuration. In addition, there is no time-consuming coordination between the customer and PROTIQ to define a printable design, prepare a quote and trigger a final order. Rather, a price is calculated in real time and the order can be placed online.

paramate's underlying algorithms ensure that each automatically generated model design is optimized for the additive manufacturing process that follows. Defects in the design of gear systems are also prevented: Gear pairings generated in the online configurator are precisely matched to each other. The materials available are polyamide 6x (PA6x) and tool steel (MS1 - 1,2709).

“The next step is to use double helix gearing to address geometries that are difficult to produce using conventional manufacturing methods. And of course, we already have ideas for other configurators on the PROTIQ Marketplace in addition to the inductors and gears.

trinckle is an excellent partner on this journey for us. The Berlin team works closely with us in a professional and goal-oriented manner: a cooperation that brings positive results and is fun for both sides.”

DR. RALF GÄRTNER, MANAGING DIRECTOR OF PROTIQ GMBH.

Photography:

© Steve Bergmann / trinckle 3D

Dr. Ole Bröker

Head of Business

Development & Consulting

+ 49 (0) 33 022 094 740